Boost Your Business with Automated Welding Robot Machine

Introduction

Welcome to Cresco Custom Metals, a leading provider of high-quality metal fabrication services. In today's competitive business landscape, it's crucial to adopt innovative technologies that enhance productivity and efficiency. This article will explore the transformative power of automated welding robot machines and how they can revolutionize your metal fabrication business.

The Rise of Automated Welding Robot Machines

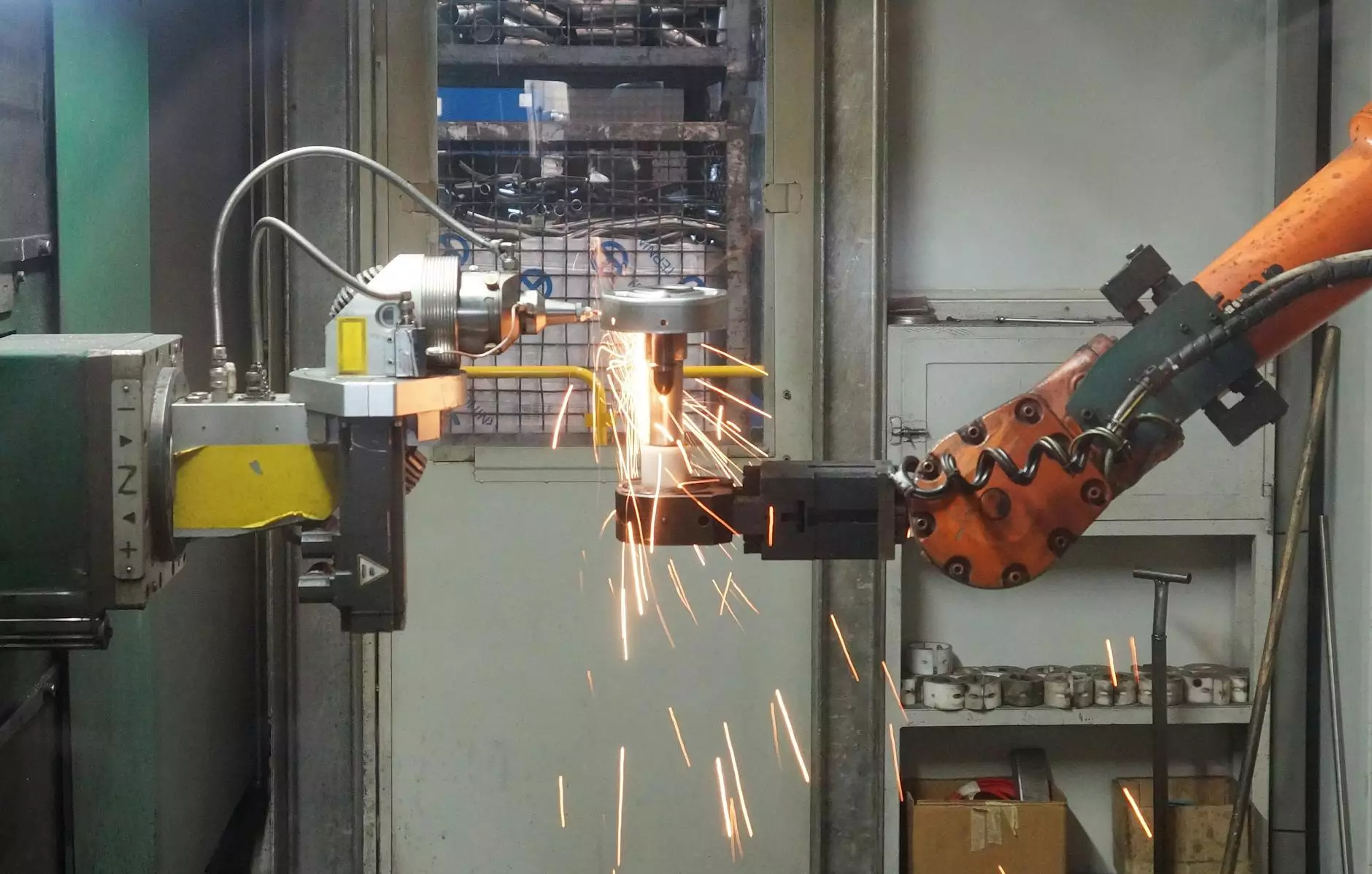

Metal fabrication has come a long way, and the introduction of automated welding robot machines has been a game-changer for the industry. These sophisticated machines have revolutionized the welding process, offering unparalleled precision, speed, and consistency.

Automated welding robot machines are designed to perform complex welding tasks with minimal human intervention. They are equipped with advanced sensors and programming capabilities that ensure precise weld placement and accurate joint configurations. With their ability to execute repetitive tasks at a rapid pace, these machines significantly reduce production time while maintaining the highest quality standards.

Benefits of Automated Welding Robot Machines

Investing in an automated welding robot machine from Cresco Custom Metals can provide numerous advantages for your metal fabrication business. Let's explore some of the key benefits:

1. Increased Productivity

The use of automated welding robot machines allows for continuous production, eliminating the need for manual labor and the associated downtime. With round-the-clock operation and minimal supervision, these machines can significantly increase your overall productivity and output. They can handle complex welding tasks with ease, ensuring higher efficiency and faster turnaround times.

2. Enhanced Precision

Automated welding robot machines offer unparalleled precision, resulting in consistent and immaculate welds. These machines are programmed to perform welds with micron-level accuracy, ensuring tight tolerances and high-quality craftsmanship. By minimizing errors and rework, you can deliver flawless products to your customers, further establishing your reputation as a reliable metal fabricator.

3. Improved Safety

Safety is a top priority in any metal fabrication business. By implementing automated welding robot machines, you can create a safer work environment for your employees. These machines are equipped with advanced safety features, including protective barriers, sensors, and emergency stop functions. By reducing the need for manual welding, you can minimize the risk of occupational hazards, such as burns and exposure to toxic fumes.

4. Cost Savings

While the initial investment in automated welding robot machines may seem significant, they offer long-term cost savings. By streamlining your production process and reducing labor costs, you can achieve higher profits and a faster return on investment. Additionally, the precision and consistency of automated welding robot machines result in minimal material wastage, further optimizing your operational expenses.

5. Versatility and Adaptability

Automated welding robot machines can handle a wide range of welding tasks, from simple to highly complex. They can adapt to different metal types, thicknesses, and joint designs, making them ideal for various applications in the metal fabrication industry. Whether you are working on automotive components, structural frameworks, or intricate designs, these machines can meet your specific requirements with ease.

Implementing Automated Welding Robot Machines

At Cresco Custom Metals, we understand the importance of seamless integration and optimization when implementing automated welding robot machines into your metal fabrication business. Our team of experts will work closely with you to assess your specific needs and provide tailored solutions.

We offer a comprehensive range of services, including:

- Consultation: Our team will evaluate your current processes and identify areas where automated welding robot machines can deliver the maximum impact.

- Installation and Training: Our skilled technicians will set up and calibrate the machines according to your requirements. We also provide comprehensive training programs to ensure your operators can utilize the machines to their full potential.

- Optimization: We offer ongoing support to optimize the performance of your automated welding robot machines. Our experts will fine-tune the programming, ensure regular maintenance, and provide troubleshooting assistance to keep your operations running smoothly.

With Cresco Custom Metals as your trusted partner, you can unlock the true potential of automated welding robot machines and take your metal fabrication business to new heights.

Conclusion

In a rapidly evolving metal fabrication industry, staying ahead of the competition is crucial. By embracing automated welding robot machines, you can transform your business, boost productivity, and deliver exceptional results to your customers. At Cresco Custom Metals, we are committed to providing cutting-edge solutions that drive growth and success. Contact us today to embark on the journey towards a more efficient and profitable future.